Largest Range of 100% Natural Latex Mattresses

Best Quality & Price Guaranteed

Largest Range of 100% Natural Latex Mattresses

Best Quality & Price Guaranteed

100 Day Comfort Guarantee and 20 Year Warranty

100% Pure Natural Latex

We use only the best quality

100% Natural

Environmentally sustainable

Natural Latex Beds From Dawn Latex Mattresses

Dawn Latex Mattresses are Australia’s leading latex mattress specialist in Adelaide. We send our Latex Mattresses Australia wide to all major cities and towns, including Melbourne, Sydney, Brisbane, Perth, Canberra, Hobart, Darwin and Alice Springs at factory direct prices.

Best Price Guaranteed

Australia Made Factory direct prices ensure better value than our competitors

Free Delivery Australia wide within 7 – 21 days. Our Delivery service is fully insured and on time.

We simply won’t be beaten on price, quality or service.

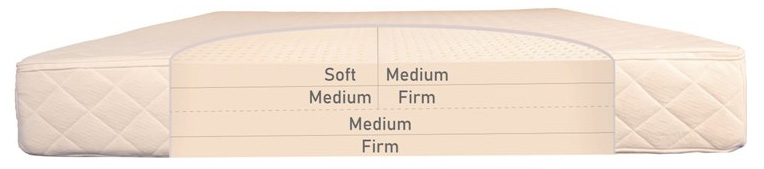

Advanced Multi Density

Mattress Finder

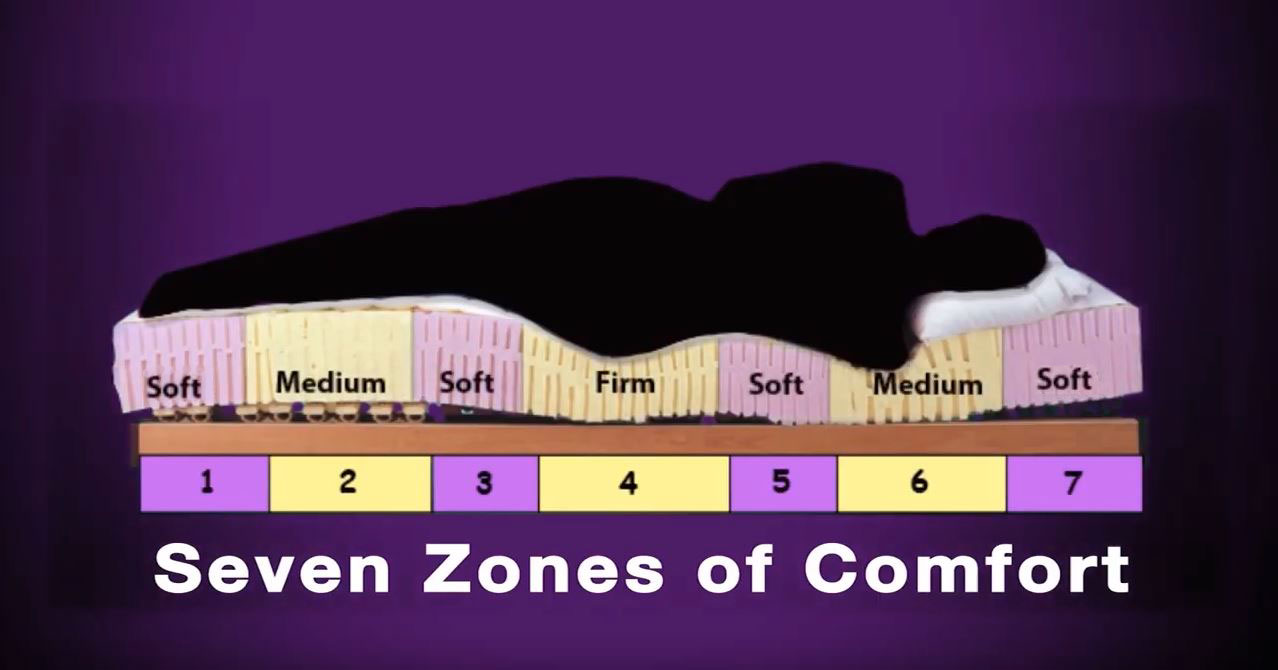

Duel Multi Density

Seven Support Zones

Gives optimum comfort and support along the length of the mattress. We can also individually customize our Duel Multi Density Latex Mattresses for couples with different density requirements. Advanced Multi Density cores allows you to easily adjust the density of your mattress at home. We use no synthetic glues any bonding of our latex is done with natural latex polymer.

Our certifications

This test evaluates the durability and the resilience characteristics of natural latex. Our 100% Natural Latex scores 99/100 points.

Click to view certificate.

GOLS

Our GOLS Latex Is 100% Certified Natural Organic

Click to view certificate.

GOTS

Our Latex Mattress Covers are made from 100% Organic Cotton.

Click to view certificate.

This test which is conducted in ABC labs, USA, evaluates the antibacterial efficacy of natural latex.

Conducted by the Twin City Corporation, USA, this test evaluates the body interface pressure for latex products.

Best Quality, Service and Price Guaranteed

Our Australia Made Factory Direct prices means genuine savings for you. To ensure you get the best value for money we will match any other comparable genuine quote of equivalent quality.

Owner Manager Brett Craig

I established Dawn Latex Mattresses 35 years ago, we have the Largest Range of 100% Natural Latex Mattresses and Hand Crafted Solid Tasmanian Oak Bed Frames in Australia and I Personally Guarantee you the Best Quality, Service and Price.

We have a comprehensive environmental policy for all our products.

Natural Latex is the most Environmentally Friendly Bedding Product, GOLS (Global Organic Latex Standard) further Guarantees minimum exploitation of the environment and workers.

We have been financial supporters of Trees For Life since 1986. Trees For Life, a Non-Profit organization established in South Australia in 1981 are extensively involved in replanting of trees and supporting our natural Flora and Fauna.

Visit our shop

For the best service and advice please phone first before visiting our Latex Mattresses Showroom.

Call 1800 822 681.

34 Cawthorne Street, Thebarton SA 5031. Enter Cawthorne Street from Phillips Street.

Dawn Latex Mattresses store location

Quick Inquiry

We would love to hear from you! Please fill out this form and we will get in touch with you shortly.